How a stretch wrapping machine supports high-volume packaging

How a stretch wrapping machine supports high-volume packaging

Blog Article

Discover the Conveniences of Utilizing a stretch wrapping machine for Reliable Packaging Solutions

Automation has brought forth considerable innovations, such as the stretch wrapping machine. What makes these makers a game-changer in the product packaging market?

Understanding the Functionality of Stretch Covering Machines

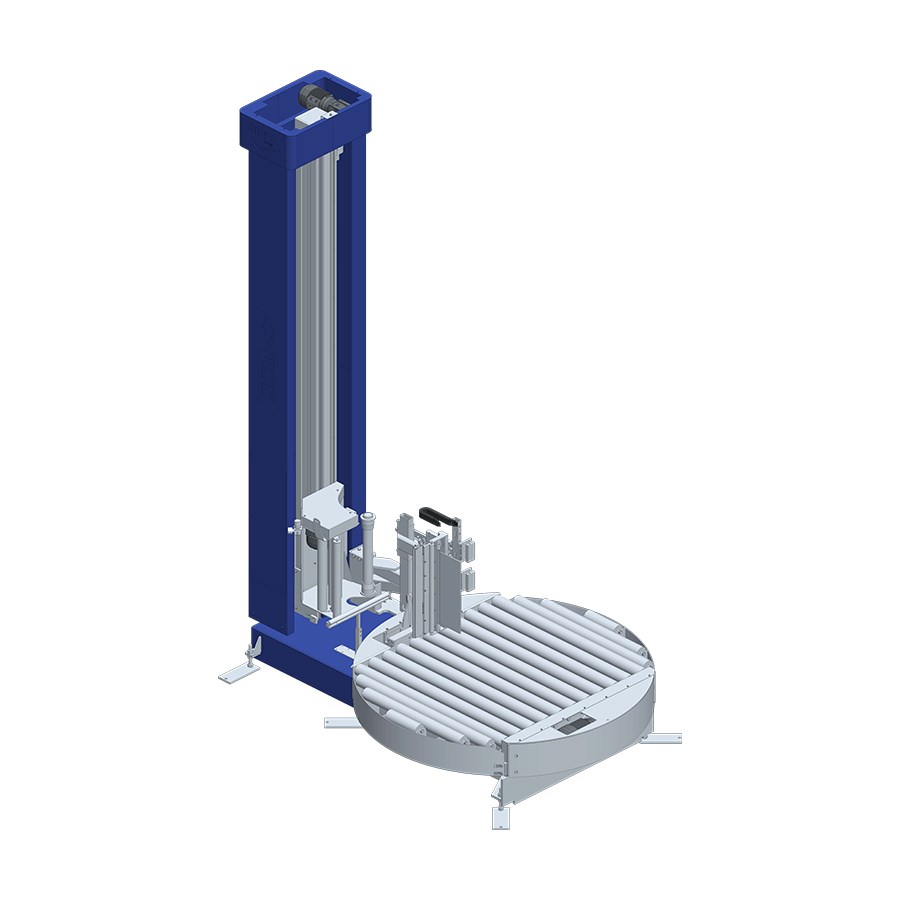

Pioneering the packaging sector, stretch covering machines simplify the process of safely product packaging things for transportation or storage space. These advanced devices use an easy yet reliable device, utilizing a stretchable plastic movie that is twisted around items, supplying security and protection. The items, frequently set up on a pallet, are revolved as the movie is given, ensuring a tight and safe and secure wrap.

The movie's flexibility offers a double purpose: it securely binds the products with each other, reducing the risk of damage as a result of activity, and it provides a barrier versus dirt, wetness, and other potential harmful aspects. The transparent nature of the stretch movie permits for very easy recognition of the packaged things.

The makers vary in their operation setting, with some being semi-automatic, calling for very little human treatment, and others being completely automatic, qualified of individually taking care of the whole covering process. No matter of their setting, stretch wrapping equipments are a keystone of safe and effective product packaging.

Just How Stretch Wrapping Machines Enhance Performance

Enhancing performance levels substantially, stretch wrapping makers enhance the packaging process with their automated abilities. These sophisticated makers enable companies to wrap a high volume of packages promptly and effectively, providing a constant wrapping result that hand-operated approaches simply can not match. This speed and uniformity translate directly into enhanced productivity, allowing services to fulfill demanding supply schedules and customer expectations.

Additionally, stretch wrapping makers call for minimal human treatment. Once the device is established and the covering parameters are set up, the equipment can run independently, freeing up employees to concentrate on other vital jobs. This automation not just minimizes labor expenses but also gets rid of human mistakes, guaranteeing the quality of covering remains constant.

Additionally, making use of stretch wrapping makers typically causes less downtime. stretch wrapping machine. With their durable style and trustworthy procedure, these devices are less prone to break downs and upkeep concerns, guaranteeing undisturbed process and improved productivity

Minimizing Product Waste With Stretch Covering Machines

While enhancing efficiency, stretch covering equipments also play a crucial role in decreasing product waste. The accuracy of these machines makes certain that each package is covered with the precise quantity of material needed, decreasing excess waste. This accuracy not only causes a cosmetically pleasing and regular bundle, however additionally contributes significantly to environmental sustainability.

Fundamentally, the use of stretch covering machines in a product packaging line is not only a step in the direction of reliable performance, however additionally a leap in the direction of environmentally friendly practices by dramatically reducing material waste.

Price Reduction: A Trick Advantage of Stretch Covering Machines

In addition to mitigating product waste, an additional substantial advantage of stretch wrapping machines is their possibility for price decrease. These makers are reliable, requiring much less manual labor for packaging goods, thus reducing down on labor prices.

Additionally, stretch wrapping makers use less product to package items safely as compared to standard wrapping approaches. This reliable usage of materials not only lowers waste however additionally decreases expenditure on packaging products.

The devices likewise reduce damage to products during transportation. With safe and secure and sturdy packaging, the risk of item damages declines, minimizing the prices related to product returns and substitutes.

Finally, the rate and efficiency of stretch covering machines can boost manufacturing rates. Faster packaging times Read Full Article imply that organizations can package and ship more items in less time, enhancing total performance.

Executing Stretch Wrapping Machines in Your Product Packaging Refine

Provided the excellent benefits of stretch wrapping equipments, including them into your packaging procedure can be a game-changing choice. An assessment of the existing packaging procedure is required to establish the optimal device type and dimension.

Educating team on device operation is important. This consists of understanding the maker's functionalities, fixing typical issues, and sticking to safety guidelines. By doing so, companies can ensure an efficient, cost-efficient product packaging process, gaining the full advantages of their investment in stretch wrapping equipments.

Verdict

In final thought, stretch covering machines provide efficient, cost-efficient product packaging options. These makers make sure product stability and security, while also providing aesthetically pleasing plans.

As soon as the device is set up and the covering parameters are configured, the device can operate learn the facts here now independently, releasing up workers to concentrate on other vital tasks.While boosting productivity, stretch wrapping makers also play an important duty in reducing product waste.Given the excellent benefits of stretch wrapping devices, integrating them right into your product packaging procedure can be a game-changing decision - stretch wrapping machine. By doing so, businesses can make sure an efficient, cost-effective packaging procedure, gaining the complete benefits of their investment in stretch wrapping equipments

In verdict, stretch covering equipments offer effective, cost-effective product packaging remedies.

Report this page